As manufacturers embrace digitization, cybercriminals are increasingly creative when targeting this high-value sector. From data loss to intellectual property theft, the damage can be severe and can affect both business operations and reputation. According to the 2022 Data Breach Investigations Report by Verizon, the manufacturing industry experienced 338 successful data breaches in the past year (out of over 2,300 attempts).

What data gets stolen the most, and what can your business do to increase data loss protection so it doesn’t happen to you? Let’s take a look at the details:

What type of data needs to be protected?

The manufacturing industry is a prime target for cybercrimes, and it all comes down to two things: money and secrets. Hackers are motivated by the prospect of financial gain or the opportunity to steal trade secrets and confidential information.

While personal information and login credentials are always at risk of being stolen in a data breach, the manufacturing industry faces an additional challenge – the threat to their intellectual property.

So, not only do manufacturers need to have solid data loss prevention (DLP) measures in place, they also need to be proactive in protecting know-how and trade secrets. It's crucial to keep this in mind when it comes to safeguarding your business against cyber threats.

The top cybercrimes affecting the manufacturing sector

Let’s talk a little bit about how data loss in the manufacturing industry actually happens.

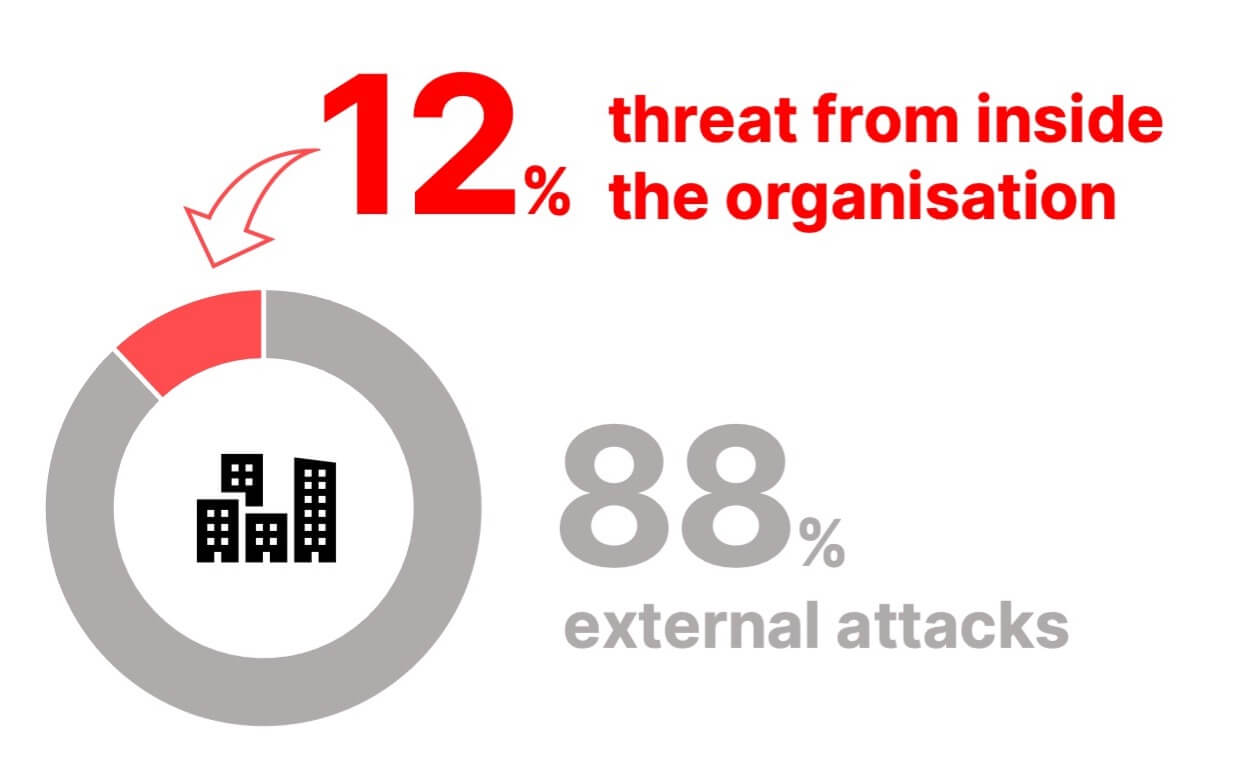

Verizon’s Data Breach report revealed that the most common types of data breaches in manufacturing were system intrusion, basic web application attacks, and social engineering. It’s also interesting to know that while 88% of attacks are external, 12% come from inside the organization.

On the rise is the use of ransomware. Ransomware attacks involve locking up important data and files so the company can't access them unless they pay the cybercriminal – it’s a data hostage situation that is used as a means of extortion by cybercriminals, usually under the threat of exposing trade secrets or selling the intellectual property to competitors.

Phishing is another hacker favourite. Basically, phishing is when the cybercriminal contacts you, usually by email, with the intention of stealing your personal or organizational information. Hackers will often target individual employees as a way of gaining access to the whole organization. It's like they're sneaking in through the back door.

But the culprit that accounts for approximately 70% of incidents? DDoS (Distributed Denial of Service) attacks. A DDoS attack is designed to flood a manufacturing organization's network and servers, making them unusable. Cybercriminals flood the target system with a large number of requests or traffic from different sources at the same time, causing it to crash. If systems are down, things like assembly lines can’t function, ultimately preventing the organization from operating.

Consequences of data breaches in manufacturing

Data loss prevention in the manufacturing industry is essential to forgo potentially devastating consequences. If a cyberattack occurs, it can result in:

- Business interruptions. In manufacturing, one or more plants need to be closed or production halted, leading to a loss of productivity and revenue.

- Expensive ransomware payments without a guarantee that confidential information won’t be exploited even after payment.

- Leaked trade secrets or having intellectual property stolen and possibly sold to competitors.

We’ve talked about the need for data loss prevention many times before. Let’s talk a little more about what common cyberattacks can cause for manufacturing companies:

DDoS attacks have a crippling effect on manufacturing companies. They can overwhelm the company's systems by sending massive amounts of traffic to it, causing the system or network to function improperly. This can bring production to a complete standstill and disrupt services, leading to frustrated customers and lost revenue. In extreme cases, a DDoS attack could even damage equipment, leading to costly repairs or replacements.

One of the most expensive consequences of a data breach (and poor data loss protection) is ransomware payments. Hackers can encrypt sensitive information and demand a significant ransom for its safe return to the organization. Of course, since this involves dealing with shady characters, there’s no guarantee that paying these criminals will stop them from exploiting the data.

In manufacturing, the importance of intellectual property protection is greater than in many other industries, because it is such a valuable asset in this sector. Protecting know-how and intellectual property is essential to prevent data loss, reputation damage, and can even lead to long-term damage to the company's competitive edge.

How manufacturing companies can improve their DLP

In a nutshell:

- Multi-layer security infrastructure

- Classify and encrypt sensitive data and employ Zero Trust policy

- Keeping software up-to-date (patching up vulnerabilities as soon as possible)

- Regular data backup

- Regular risk assessments

- Develop and implement security policies and procedures, and have response plans ready

- Educate employees

No matter how you look at it, it's crucial to have data loss prevention measures in place.

Implementing DLP measures is crucial to prevent data loss and protect know-how. One effective approach is using data classification and encryption to protect sensitive data. By classifying data and encrypting it based on its sensitivity, manufacturers can ensure that only authorized individuals have access to it. Look into the Zero Trust Approach to see how and why access needs to be limited.

Protecting know-how refers to confidential knowledge that gives a company a competitive advantage. Know-how can include trade secrets, processes, schematics, and other intellectual property. To protect know-how, manufacturers can implement access controls, such as multi-factor authentication and user permission settings, as well as make sure they have an intrusion detection system in place.

In addition to protecting intellectual property and confidential data, manufacturers should also ensure that their employees are trained in cybersecurity best practices. This includes regular training and awareness programs to educate employees on how to detect and prevent data breaches. It’s also a good idea to implement policies and procedures that enforce data protection measures, such as password policies and incident response plans.

How to prevent the loss of manufacturing know-how with Safetica? Download our whitepaper for manufacturers

Next articles

Strengthening Data Loss Prevention (DLP) in AWS

A comprehensive guide to Data Loss Prevention (DLP) in Amazon Web Services (AWS), outlining key features and strategies for protecting sensitive data. Explore how integrating Safetica can enhance AWS's native DLP capabilities.